miller bobcat 250 parts manual pdf

Welcome to the Miller Bobcat 250 Parts Manual, your essential guide for understanding and maintaining your equipment. This comprehensive resource provides detailed parts listings, safety information, and maintenance tips to ensure optimal performance and longevity of your Miller Bobcat 250. Designed for both professionals and DIY enthusiasts, this manual is your go-to reference for troubleshooting, repairs, and upgrades. Explore the structure, features, and best practices for using this manual effectively to keep your equipment running smoothly.

1.1 Overview of the Manual

The Miller Bobcat 250 Parts Manual is a detailed resource designed to help users understand, maintain, and repair their equipment effectively. It includes comprehensive parts listings, safety guidelines, and troubleshooting tips. This manual serves as a go-to reference for identifying components, understanding technical specifications, and ensuring proper maintenance. Whether you’re a professional technician or a DIY enthusiast, this guide provides clear instructions and diagrams to help you manage repairs and upgrades with confidence. Its structured format ensures easy navigation, making it an indispensable tool for anyone working with the Miller Bobcat 250.

1.2 Importance of Using Genuine Parts

Using genuine Miller Bobcat 250 parts ensures optimal performance, safety, and longevity of your equipment. Genuine parts are designed to meet strict manufacturer standards, guaranteeing compatibility and reliability. Counterfeit or non-genuine parts can compromise safety, lead to equipment damage, and void warranties. Always prioritize authentic components to maintain your equipment’s integrity and ensure compliance with safety regulations. Refer to the manual for a detailed parts list and trusted sources for procurement. This approach protects your investment and guarantees the best operational outcomes for your Miller Bobcat 250.

Key Features of the Miller Bobcat 250

The Miller Bobcat 250 is a robust, portable welder/generator designed for versatility and durability. It supports MIG, TIG, and stick welding, with a powerful 250-amp output. Its compact design allows easy transport, while the integrated generator provides auxiliary power for tools, making it ideal for fieldwork and construction sites. The welder also features advanced controls for precise arc adjustment and a rugged build to withstand harsh environments, ensuring reliable performance in demanding conditions.

2.1 Technical Specifications

The Miller Bobcat 250 is a versatile welder/generator with a 250-amp welding output and 5,500 watts of peak generator power. It operates at 120/240 volts and features a 60 Hz frequency. The unit supports MIG, TIG, and stick welding processes, making it suitable for various applications. Weighing approximately 542 pounds, it is designed for portability and durability. The generator includes a 12-gallon fuel tank for extended runtime, delivering up to 8 hours of continuous operation. The welder also boasts a 100% duty cycle at 250 amps, ensuring consistent performance for demanding tasks. Its robust design and advanced controls make it ideal for construction, fabrication, and fieldwork environments.

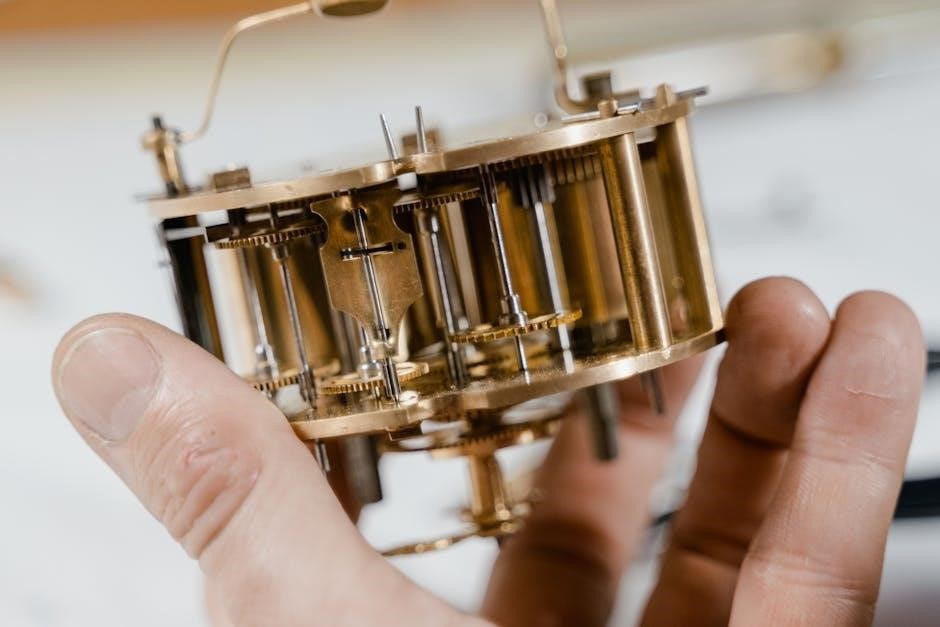

2.2 Types of Parts Covered in the Manual

The Miller Bobcat 250 Parts Manual provides a detailed catalog of components, including engine parts, electrical systems, welding components, and accessories. It covers essential items like electrodes, welding guns, cables, and generators. The manual also lists internal components such as gears, bearings, and fuel system parts. Additionally, it includes filters, belts, and other consumables. Each part is identified with specific numbers and descriptions, ensuring easy identification and ordering. This comprehensive listing helps users maintain, repair, and upgrade their equipment efficiently, ensuring optimal performance and longevity of the Miller Bobcat 250.

Safety Information and Precautions

Always read the safety information at the beginning of the manual and in each section. Use only genuine replacement parts from the manufacturer. Wear proper PPE when handling equipment. Follow all safety guidelines to avoid hazards and ensure safe operation and maintenance of your Miller Bobcat 250.

3.1 General Safety Guidelines

The Miller Bobcat 250 Parts Manual emphasizes the importance of safety to prevent accidents and ensure proper equipment operation. Always read the safety information at the beginning of the manual and in each section. Wear proper personal protective equipment (PPE), such as gloves and safety goggles, when handling parts or performing maintenance. Use only genuine replacement parts from the manufacturer to maintain equipment integrity. Follow all safety guidelines and precautions to avoid hazards associated with electrical components, hot surfaces, and moving parts. Regularly inspect equipment for damage or wear and adhere to the recommended maintenance schedule. Prioritize safety to protect yourself and ensure optimal equipment performance.

3.2 Safety Precautions When Handling Parts

When handling parts for your Miller Bobcat 250, always follow safety precautions to avoid injury and damage; Ensure parts are stored properly to prevent loss or damage. Handle heavy components with care, using appropriate lifting tools to avoid strain. Never use damaged or worn-out parts, as they can compromise equipment performance and safety. Wear gloves and protective eyewear when handling sharp or heavy components. Avoid touching electrical parts without proper grounding to prevent shocks. Follow the manual’s guidelines for safe part replacement and disposal. Prioritize caution to ensure safe and effective maintenance of your Miller Bobcat 250.

Understanding the Parts Manual

The Miller Bobcat 250 Parts Manual is a comprehensive resource designed to help users identify, understand, and replace parts efficiently. It includes detailed diagrams, part numbers, and descriptions to guide maintenance and repairs, ensuring accurate and safe procedures. This manual is essential for anyone working with the Bobcat 250, providing clear instructions to maximize equipment performance and longevity. By following the manual, users can ensure their equipment operates at peak efficiency and safety standards are maintained; Regular reference to this manual is recommended for optimal results.

4.1 How to Read the Manual

Reading the Miller Bobcat 250 Parts Manual requires a systematic approach to ensure clarity and effectiveness. Begin by reviewing the table of contents to familiarize yourself with the structure. Use the index to locate specific parts or sections quickly. Pay attention to detailed diagrams, which provide visual guidance for identifying components. Refer to the parts list for accurate descriptions and numbers. Always cross-check information with safety guidelines and maintenance tips. By following this method, you can efficiently navigate the manual, ensuring proper understanding and application of its content for optimal equipment performance and safety.

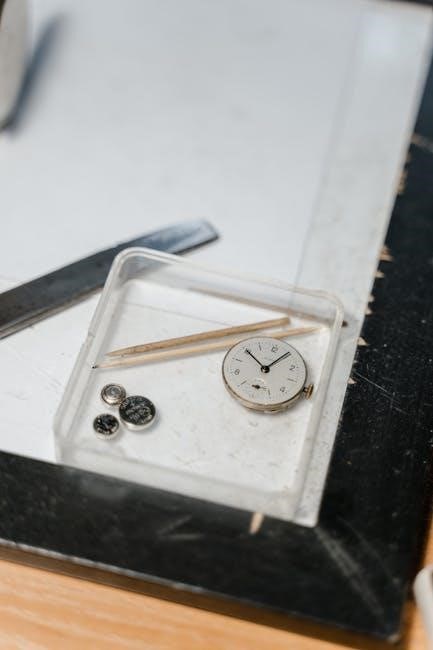

4.2 Structure of the Parts Diagrams

The parts diagrams in the Miller Bobcat 250 manual are organized to provide clear visual representation of components. Each diagram is divided into sections, showcasing main assemblies and their subsystems. Exploded views highlight individual parts, while numbered callouts correspond to the parts list. Color coding and symbols differentiate materials and assembly steps. Labels indicate component names and quantities, ensuring accurate identification. Cross-referencing with the parts catalog simplifies ordering replacements. Understanding this structure enables users to locate and identify parts efficiently, streamlining maintenance and repair processes. Familiarity with these diagrams enhances troubleshooting and assembly accuracy.

Parts Catalog and Identification

The Miller Bobcat 250 parts catalog provides a detailed inventory of components, ensuring easy identification and replacement. Organized by category, each part is listed with corresponding numbers, descriptions, and diagrams. Users can cross-reference components using the manual’s index or visual guides. This system streamlines maintenance by allowing quick lookup of specific parts. The catalog also includes subsystems and assemblies, making it easier to locate related components. Proper identification ensures compatibility and prevents installation errors. Referencing this section is crucial for accurate part selection and ordering.

5.1 Main Components of the Bobcat 250

The Miller Bobcat 250 is composed of key components essential for its operation. The engine powers the system, providing energy for welding and generation. The generator converts mechanical energy into electrical power, while the welding system delivers precise arc control. The control panel houses essential controls and indicators for monitoring operations. Additional components include the cooling system, ensuring optimal temperature regulation, and the fuel system, which powers the engine. Each part is designed for durability and efficiency, contributing to the overall performance and reliability of the Bobcat 250. Understanding these components is crucial for effective maintenance and operation.

5.2 How to Identify Parts Using the Manual

Identifying parts in the Miller Bobcat 250 manual is straightforward with its organized structure. Start by locating the parts diagrams section, which provides detailed visual representations of each component. Use the part numbers listed in the diagrams to cross-reference with the parts catalog. Pay attention to descriptions and quantities to ensure accuracy. For easier navigation, utilize the index or search function to find specific parts quickly. Always verify compatibility by matching model numbers and specifications. This method ensures precise identification and simplifies the process of ordering or replacing components, making maintenance and repairs more efficient and stress-free.

5.3 Cross-Reference Guide for Parts

The cross-reference guide in the Miller Bobcat 250 manual helps users match parts with their corresponding diagrams and descriptions. This section allows quick lookup of components by part number, model, or description, ensuring accurate identification. It also links related parts, making it easier to find compatible or interchangeable items. Use this guide to verify part compatibility, avoid mismatches, and streamline the ordering process. By organizing parts logically, the cross-reference guide reduces confusion and saves time when searching for specific components, ensuring efficient maintenance and repair workflows for your Miller Bobcat 250 equipment.

Troubleshooting and Maintenance

This section provides detailed steps for identifying and resolving common issues with your Miller Bobcat 250. Regular maintenance schedules and tips are included to ensure longevity and optimal performance.

6.1 Common Issues and Solutions

Common issues with the Miller Bobcat 250 include faulty spark plugs, clogged air filters, and coolant leaks. Replace spark plugs every 100 hours and clean or replace air filters regularly. Inspect hoses for cracks and tighten loose connections to prevent coolant leaks. If the engine stalls, check fuel levels and ensure the choke is functioning properly. For electrical issues, verify circuit breakers and fuses. Refer to the manual for specific troubleshooting steps and always use genuine parts for repairs to maintain performance and warranty validity.

6.2 Maintenance Schedule

Regular maintenance is crucial for the longevity and performance of your Miller Bobcat 250; Follow a routine schedule: daily checks for oil levels, air filter cleanliness, and coolant status. Every 50 hours, inspect and replace spark plugs if necessary. Clean or replace the air filter every 100 hours. Check coolant hoses for cracks and tighten connections. Annually, replace belts and perform a thorough inspection of electrical components. Refer to the manual for detailed intervals and procedures. Adhering to this schedule ensures optimal performance, prevents breakdowns, and extends the lifespan of your equipment.

Ordering Replacement Parts

Ordering replacement parts for your Miller Bobcat 250 is straightforward. Use the parts manual to identify the correct part numbers, then visit the Miller Electric website or contact their customer support for assistance. Ensure genuine parts are purchased to maintain performance and warranty validity. Always verify part compatibility before placing an order to avoid delays or returns.

7.1 How to Order Parts Online

To order Miller Bobcat 250 parts online, visit the official Miller Electric website. Create an account or log in if you already have one. Navigate to the “Parts” section and search by part number, which can be found in your parts manual. Select the desired items, add them to your cart, and proceed to checkout. Ensure all part numbers match your manual to avoid errors. Payment is typically secure, with options like credit cards or PayPal. After placing your order, you’ll receive a confirmation email with tracking details. For any issues, contact Miller’s customer support team for assistance.

7.2 Contact Information for Miller Electric

For inquiries or assistance with Miller Bobcat 250 parts, contact Miller Electric directly. Their official website provides a “Contact Us” section with detailed information. You can reach them via phone at 1-800-426-4553 or email through their online form. Miller Electric Mfg. Co. is located at 1635 West Spencer Street, Appleton, WI 54914. Visit their website for regional offices and international support. This ensures you receive genuine parts and expert guidance, maintaining your equipment’s performance and warranty compliance. Their customer service team is available to address any questions or concerns.

Downloading the Manual

Access the Miller Bobcat 250 Parts Manual PDF directly from Miller Electric’s official website. Ensure authenticity and the latest updates by downloading from trusted sources only.

8.1 Steps to Download the PDF Manual

To download the Miller Bobcat 250 Parts Manual PDF, visit the official Miller Electric website. Navigate to the “Support” or “Resources” section, where you’ll find a dedicated portal for manuals. Search for “Bobcat 250” in the provided search bar. Select the correct manual from the results, ensuring it matches your model. Click the download link to save the PDF. For added convenience, some authorized distributors also offer direct downloads. Always verify the source to ensure you’re accessing the genuine and updated version of the manual.

8.2 Sources for the Miller Bobcat 250 Manual

The Miller Bobcat 250 Parts Manual PDF is available through several trusted sources. The official Miller Electric website provides a dedicated section for manuals, ensuring authenticity and updates. Additionally, authorized Miller distributors and online marketplaces like Amazon offer genuine PDF downloads. Platforms such as Weldfabulous specialize in Miller parts and manuals, while community forums occasionally share verified links. Always verify the source to ensure you’re downloading the correct and updated version of the manual for your specific model.

Additional Resources

Visit the official Miller Electric website for comprehensive guides, or explore community forums for user discussions and tips. Check specialized stores like Weldfabulous for parts and manuals.

9.1 Official Miller Electric Website

The official Miller Electric website is a primary resource for the Miller Bobcat 250 parts manual and related information. It offers a detailed parts catalog, troubleshooting guides, and maintenance schedules. Users can download the PDF manual directly or explore the extensive library of technical documents. Additionally, the website provides access to customer support, warranty information, and genuine parts ordering. It serves as a one-stop destination for all your Miller Bobcat 250 needs, ensuring you have the most accurate and up-to-date resources to maintain and repair your equipment effectively.

9.2 Community Forums and Support Groups

Community forums and support groups are invaluable resources for Miller Bobcat 250 users. Platforms like Miller Electric’s official forums, welding communities, and social media groups offer a space to discuss repairs, share tips, and troubleshoot issues. Users can engage with experts and peers, gaining insights from real-world experiences. These forums often include discussions on parts identification, maintenance, and upgrades. Participating in these communities can enhance your understanding of the equipment and provide practical solutions to common challenges. By connecting with others, you can optimize your use of the Miller Bobcat 250 and resolve issues more efficiently.

Tips for Using the Manual Effectively

Use the index to quickly locate parts and sections. Refer to diagrams for visual clarity. Update the manual regularly for the latest information and safety guidelines to ensure safe and efficient operations.

10.1 Best Practices for Referencing the Manual

To maximize the effectiveness of the Miller Bobcat 250 Parts Manual, adopt these best practices: Always start by reviewing the safety information and precautions. Use the index to quickly locate specific parts or sections. Cross-reference parts diagrams with written descriptions for clarity. Highlight important pages or sections for easy access. Regularly update your manual with the latest revisions or supplements. Refer to the troubleshooting guide before attempting repairs. Keep the manual in a clean, dry environment to prevent damage. By following these practices, you ensure accurate referencing and maintain the integrity of your equipment.

10.2 How to Keep the Manual Updated

To keep the Miller Bobcat 250 Parts Manual updated, visit the official Miller Electric website regularly for the latest PDF versions. Subscribe to their newsletter or support notifications for update alerts. Cross-check your manual with the online version to ensure you have the most recent revisions. Print or download updates and insert them into your manual. For physical copies, maintain an organized binder with clear section dividers. Consider bookmarking the manual’s download page for quick access. Regular updates ensure you have the latest parts information, safety guidelines, and troubleshooting tips, optimizing your equipment’s performance and longevity.

Industry Applications of the Bobcat 250

The Miller Bobcat 250 is widely used in welding and fabrication, construction, and heavy machinery industries. Its versatility makes it ideal for various industrial applications, ensuring reliability and efficiency in demanding environments.

11.1 Welding and Fabrication

The Miller Bobcat 250 excels in welding and fabrication, offering exceptional portability and versatility for professionals. Its robust design handles MIG, TIG, and Stick welding seamlessly, making it ideal for metalworking shops and fieldwork. The machine’s consistent arc performance ensures high-quality welds, while its generator capability powers tools on-site. Widely used in automotive repair, construction, and custom fabrication, the Bobcat 250 supports precision and durability. Its reliability in demanding environments makes it a cornerstone in industrial and creative welding projects, ensuring efficient and professional results across various applications.

11.2 Construction and Heavy Machinery

The Miller Bobcat 250 is a reliable workhorse in construction and heavy machinery environments, delivering consistent power for welding and generator needs. Its portability and durability make it ideal for on-site repairs and maintenance of large equipment. Common applications include repairing excavators, bulldozers, and cranes, as well as welding steel structures and frameworks. The machine’s high-duty cycle ensures it can handle demanding jobs in tough conditions. Whether it’s fabricating components or powering tools, the Bobcat 250 is essential for keeping construction projects on track, offering the versatility and reliability needed in the field.

12.1 Summary of Key Points

The Miller Bobcat 250 Parts Manual is an exhaustive guide designed to help users understand, maintain, and repair their equipment effectively. It covers technical specifications, safety protocols, and detailed parts diagrams, ensuring clarity and precision. The manual emphasizes the importance of using genuine Miller parts to maintain performance and durability. Key sections include troubleshooting tips, maintenance schedules, and a comprehensive parts catalog. By adhering to the manual’s guidelines, users can extend the lifespan of their equipment and ensure optimal functionality. This resource is indispensable for both professionals and DIY enthusiasts, providing a clear path to efficient and safe operations.